| No comment |

Your Position: Home

> Motion Control System > Stepper Drive&Motor > Gear Reduction Motor > Ratio1:10 NEMA34 4A 3NM 429oz-in L 66mm Gear Reduction Motor+Drive CNC RouterDescription

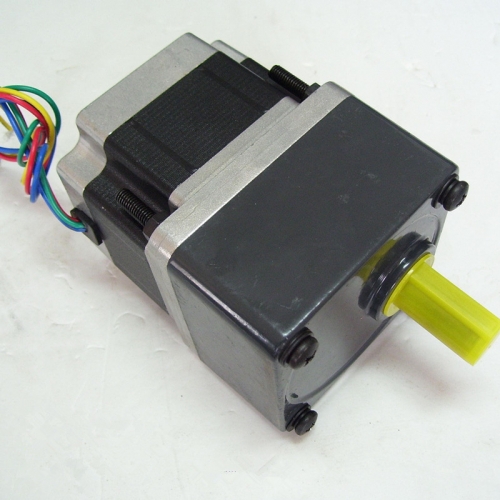

Ratio1:10 NEMA34 4A 3NM 429oz-in L 66mm Gear Reduction Motor+Drive CNC Router 86HS6640A4G10+MA860H

Appliaction:

Inject printers, Textile Equipment, Embroidery Machine, Precision Telescope Positioning Systems, engraving machine, packaging machinery, CNC numerically-controlled machine tool and transmission.

Motor Product Description:

Step Angle Accuracy: ±5%(full step, no load)

Resistance Accuracy: ±10%

Inductance Accuracy: ±20%

Temperature Rise: 80 Degrees Celsius Max.(rated current,2 phase on)

Ambient Temperature: -20°C-+50°C

Insulation Resistance: 100MΩ Min.500V DC

Dielectric Strength: 500V AC for one minute

There are multiple choice for 86BYG series geared motor. if you any other choice, please please do contact us for a better solution.

Motor Length: 66mm 80mm 98mm 114mm 126mm 156mm

Gear Ratio: 1:3 1:5 1:7.5 1:10 1:12.5 1:15 1:20 1:25 1:30 1:40 1:50 1:75 1:150 1:180

Reduction box: 90*90*45mm(Gear Ratio<20)

Reduction box: 90*90*60mm(Gear Ratio>=20)

Gear Reduction Motor Specifications

Model | Step Angle | Rated Current (A) | Phase Resistance (ohm) | Phase Inductance (mH) | Holding Torque (N*m) | Detent Torque (N*cm) | Rotor Inertia (g*cm2) | Motor Length (mm) |

86HS6640A4 | 1.8 | 4 | 0.6 | 1.6 | 3 | 5.5 | 850 | 66 |

86HS8040A4 | 1.8 | 4 | 0.75 | 5.6 | 4 | 6.5 | 1050 | 80 |

86HS9860A4 | 1.8 | 6 | 0.33 | 2.4 | 6.5 | 9.5 | 1550 | 98 |

86HS11460A4 | 1.8 | 6 | 0.5 | 2.1 | 8.2 | 12.5 | 1800 | 114 |

86HS12660A4 | 1.8 | 6 | 0.65 | 3.5 | 9.5 | 18.5 | 2200 | 126 |

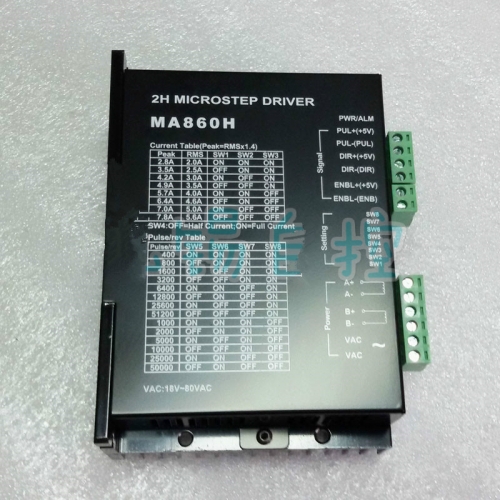

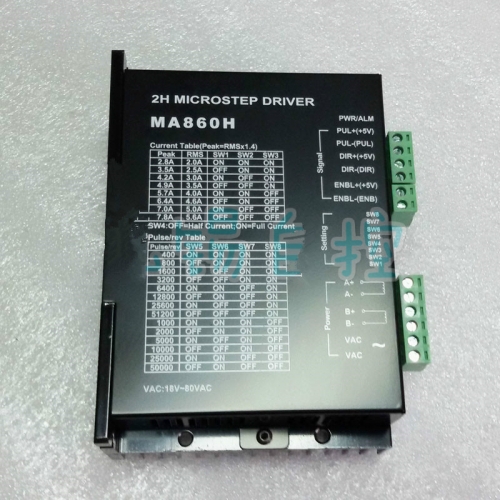

Stepper Drive Specifications

Item | Min | Typical | Max | Unit |

Power supply | 24 | - | 110 | VDC |

18 |

| 80 | VAC | |

Average output current | 2 | 2.5 | 7.8 | A |

Logic input current | 6 | 15 | 30 | mA |

Impulse response frequency | - | - | 100 | KHZ |

Pulse low level | 5 | - | 1 | μS |

Drive Wiring Description

Signal | Function |

PUL | Pulse signal: rising edge, the pulse from low to high is to go a step angle motor |

DIR | Direction signal: TTL-level driver to change the direction |

OPTO | Optocoupler drive power |

ENA | Enable signal: block or allow the drive to work, low-level ban |

GND | DC power supply ground |

+V | DC power supply positive (typical 24VDC) |

A+ | Motor Phase A |

A- | Motor Phase A |

B+ | Motor Phase B |

B- | Motor Phase B |

Ratio1:10 NEMA34 4A 3NM 429oz-in L 66mm Gear Reduction Motor+Drive CNC Router 86HS6640A4G10+MA860H

Appliaction:

Inject printers, Textile Equipment, Embroidery Machine, Precision Telescope Positioning Systems, engraving machine, packaging machinery, CNC numerically-controlled machine tool and transmission.

Motor Product Description:

Step Angle Accuracy: ±5%(full step, no load)

Resistance Accuracy: ±10%

Inductance Accuracy: ±20%

Temperature Rise: 80 Degrees Celsius Max.(rated current,2 phase on)

Ambient Temperature: -20°C-+50°C

Insulation Resistance: 100MΩ Min.500V DC

Dielectric Strength: 500V AC for one minute

There are multiple choice for 86BYG series geared motor. if you any other choice, please please do contact us for a better solution.

Motor Length: 66mm 80mm 98mm 114mm 126mm 156mm

Gear Ratio: 1:3 1:5 1:7.5 1:10 1:12.5 1:15 1:20 1:25 1:30 1:40 1:50 1:75 1:150 1:180

Reduction box: 90*90*45mm(Gear Ratio<20)

Reduction box: 90*90*60mm(Gear Ratio>=20)

Gear Reduction Motor Specifications

Model

Step Angle

Rated Current (A)

Phase Resistance

(ohm)

Phase Inductance

(mH)

Holding Torque

(N*m)

Detent Torque

(N*cm)

Rotor Inertia

(g*cm2)

Motor Length

(mm)

86HS6640A4

1.8

4

0.6

1.6

3

5.5

850

66

86HS8040A4

1.8

4

0.75

5.6

4

6.5

1050

80

86HS9860A4

1.8

6

0.33

2.4

6.5

9.5

1550

98

86HS11460A4

1.8

6

0.5

2.1

8.2

12.5

1800

114

86HS12660A4

1.8

6

0.65

3.5

9.5

18.5

2200

126

Stepper Drive Specifications

Item

Min

Typical

Max

Unit

Power supply

24

-

110

VDC

18

80

VAC

Average output current

2

2.5

7.8

A

Logic input current

6

15

30

mA

Impulse response frequency

-

-

100

KHZ

Pulse low level

5

-

1

μS

Drive Wiring Description

Signal

Function

PUL

Pulse signal: rising edge, the pulse from low to high is to go a step angle motor

DIR

Direction signal: TTL-level driver to change the direction

OPTO

Optocoupler drive power

ENA

Enable signal: block or allow the drive to work, low-level ban

GND

DC power supply ground

+V

DC power supply positive (typical 24VDC)

A+

Motor Phase A

A-

Motor Phase A

B+

Motor Phase B

B-

Motor Phase B